Managing Stock Levels

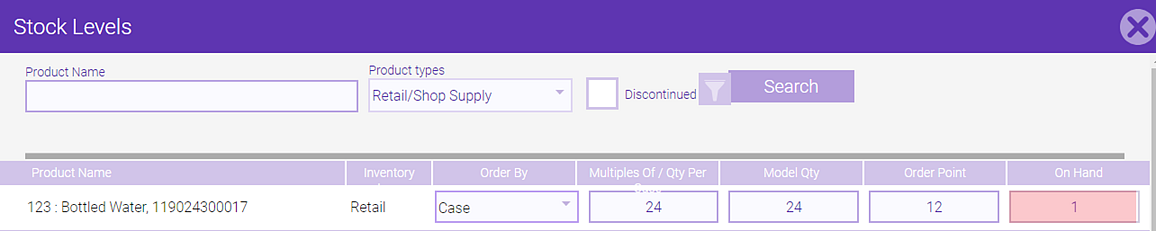

The Stock Levels screen is where you define ordering details and ordering thresholds for products, while the Purchase Order screen is where you'll create POs that replenish your stock levels.

When you enable inventory tracking for a product, the product is automatically added to the Stock Levels list. To remove a product from the Stock Levels list, simply turn off inventory tracking in the product's maintenance form.

Note: You can also configure stock level settings via a product's definition.

To use filters and search for products

- Use the filters across the top of the table to narrow down the list.

- Product Name: Enter a product name, SKU, Barcode, or variant name to filter the list.

- Product Types: Select an Inventory Type to view products of that type. Inventory Type is defined for each product's maintenance form.

Note: Shop Supply products appear with blue text in the Inventory Count, Inventory Returns, Purchase Orders, Stock Levels, and PO Receival screens.

- Include discontinued: Includes discontinued products in search results. The following icon appears beside discontinued products:

- Show only low inventory: Only displays items whose On Hand was less than or equal to their Order Point as of the end of the previous day. This option looks at the previous night's inventory roll-up, so inventory changes made in the current day will not be reflected in results until the following day.

- Advanced Search: Search by Manufacturer, Distributor, Product Category/subcategory, or Supply Category.

- When finished defining filters, select Search to apply them.

To manage stock levels

Note: If your business consists of Central Office and multiple locations, see Stock Levels in Central Office for details on how Stock Levels are affected.

- After searching, select Edit.

- Order By: Your selection here impacts how product quantities are calculated on the Purchase Order screen:

- Each: If you select this option, you will be able to order the product in the exact quantity that you define in the Purchase Order.

- Case: If you select this option, you will be able to order the product by the case, which means that some orders may result in your On-Hand amount going well over your desired Model Quantity.

- If you selected Each in the Order By field: To get you to your Model Quantity, a Purchase Order's Suggested column will always suggest a quantity that is a multiple of the Multiples Of / Qty Per Case value, because the assumption is that the product comes in a package with that many units. However, note that each unit (product) added to the Purchase Order is still equal to ONE unit (product), so you will be able to order the precise quantity you need.

- If you selected Case in the Order By field: To get you to your Model Quantity, a Purchase Order's Suggested column will suggest the number of cases you need. Each unit is a case, and each case provides the number of products defined in the Multiples Of / Qty Per Case field.

- Model Qty: This is the ideal quantity of the product you wish to have on hand. The Purchase Order screen will suggest an order amount that attains this Model Qty value.

- Order Point: This defines the threshold of when a product's inventory is low and needs to be reordered. We recommend setting this value to half the Model Qty.

When the On Hand is less than or equal to the Order Point, the stock is considered low. The On Hand field turns red, indicating that the product should be reordered. Note the Order Point cannot be higher than the Model Qty.

- On Hand: The quantity of the product currently available for sale or use, as defined in Inventory Count. This field turns red when the On Hand is less than or equal to the Order Point.

- When finished, select Save.